Three ministries and commissions jointly support the graphene industry while the technology is still in experimental stage.

Graphene has been continuing to heat up in capital market for some time, and now it is favoured by the Chinese Government.

On 30 Nov., Ministry of Industry and Information Technology of the People’s Republic of China, National Development and Reform Commission, and Ministry of Science and Technology of the People’s Republic of China jointly issued a document, put forward several opinions on promoting graphene industry innovation and development.

The document points out that as the graphene material is in the crucial period of moving from the laboratory to the market, we need to make breakthroughs in the key generic technology of large-scale preparation of graphene material, strengthen the intellectual property rights protection system, build a service platform for the industry development and promote the first batch of pilot industrialized applications before expanding its applications and nurturing it to be a leading industry in China.

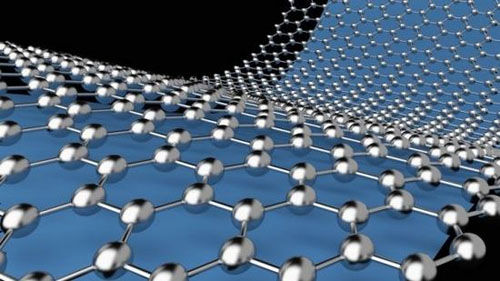

Dubbed as “the wonder material of the 21st century”, graphene has great application potential in various fields such as energy equipment, communication and transportation, aerospace, marine engineering equipment, bio-medicine and environmental protection etc.

However, the miracle won’t come easy yet. At present, the production technology of graphene material is far from mature. Beside mass production and application have not been realized, graphene still faces more difficulties: low technology commercialization rate, low-precision tool control, unstable quality performance, high production cost, stagnant standardisation, and limited commercial application fields etc.

So far, the academia have found out several methods of producing graphene such as epitaxial growth, redox, CVD, solvent stripping etc., all of which have their advantages and disadvantages in quality, cost and productivity. As a matter of fact, none of them can be used in mass production.

The primary method of producing graphene is redox, generating graphite oxide through the chemical reaction of natural graphite, strong acid and strong oxidizing substances, forming graphene oxide through ultrasonic dispersion, adding reducing agent to remove the oxygen-containing groups on the surface of graphene oxide, and finally forming graphene.

This method does not cost a lot, but the waste fluid causes heavy pollution. More importantly, what comes out though this process is multi-layer graphene or graphite crystallite, rather than graphene itself, which means that the quality cannot be guaranteed. In fact, the vast majority of the “graphene” in the market is actually graphene oxide.

Stuck in the technology bottleneck, graphene industry is still in the preliminary development phase, yet this does not bring down the expectation in the capital market. Recently, graphene sector has witnessed several surges and so far, there are already over 100 graphene companies in China. According to statistics, at least 25 listed companies in A-share market involve graphene.

"Currently, all of them are still in the early development stage and no apparent leading enterprise has emerged yet,”according to Li Yichun, Secretary-general of China Industrial Technology Strategy Graphene League.

In China, Shanghai Deluxe Family invests in graphene field on the largest scale, and its investment destination includes Ningbo Morsh Science and Technology Ltd. and Chonging Graphene Tech. Co., Ltd. The two companies have strong technical strength in graphene field, yet “it remains to be seen whether they can take the lead in the industry”.

A number of domestic companies have promoted “graphene products” in the market. “Graphene battery” is one of the hyped graphene products, which is faster in charging and discharging but remains the same in energy density. So the “graphene battery” can only the charge faster but does not last longer distance per charge.

Dr. Liu Guanwei, who has been doing research in power batter field for many years in Tsinghua University, observed “there does not exist ‘graphene battery’ in the real sense.” According to him, the probable application of graphene in lithium ion battery is conductive agent or intercalation electrode material. In either case, graphene is no better than the traditional conductive carbon black and graphite.

In terms of cost, we still cannot afford to replace carbon and graphite with graphene. Graphene powder is 1 million RMB per tonne to 3 million RMB per tonne and its thin films about 300 RMB/m2 while traditional carbon and graphite are less than or a little bit more than 100,000 RMB per tonne.

"Most of the graphene produced so far are multi-layer and need dispersion; otherwise, it is nothing but castle in the air,”Dr. Liu said. Domestic “graphene product” still remains in experimental stage and the experiment result is of low reproducibility and low output at too high a cost. “And most of the experiment results have no practical prospects in the coming 10-20 years” he added.

A large number of people assume that China has been leading the global graphene industry since the China Industrial Technology Strategy Graphene league released the 2015 Global Graphene Industry Report in October and the amount China’s research papers and the patents in the recent three years in this field rank top globally.

However, Andre Geim, the Nobel winner in 2010 and one of the discoverer of graphene, does not think so. He believes that over half of the published papers about graphene will be discarded and over 90% of the patents from universities have no practical value at all.

Professor Zhu Hongwei in the Micronano-mechanics Center in the School of Material Science and Engineering of Tsinghua University pointed out, “there are quite a few enterprises that are really doing graphene business. Most of the enterprises are speculating in the stock market or seeking national funds by making use of the graphene label while in fact they are all about carbon materials such as graphite, or not in the least relevant to graphene. ”

Zhu reveals that in some fields graphene is not irreplaceable and carbon material is also an option. Graphene enjoys but slight advantage.

Zhong Chen, CEO of Qingdao Huagao Energy Technology Co., Ltd. also believes that no more than 40 enterprises in whole China are committed to graphene industry, and very few are profiting from the business and others still get nowhere after putting in the money.

The promoting at national level is likely to accelerate graphene R&D and industalisation. Graphene, having called Chinese President Xi Jinping’s attention, will definitely be in the “13th Five-Year Plan”. Zhou Changyi, director of the energy saving department of the Ministry of Industry and Information Technology, disclosed in the 2015 Graphene Innovation Conference that the graphene industry will be on a scale of tens of billions RMB in 2020.

This article is re-edited and translated version by CCM. The original version comes from www.cnchemicals.com.

If you would like to know more about what's happening in China, please keep following us on CCM Perspective. We will keep you updated about China.